Printed Circuit Board (PCB) technology has revolutionized the way we design and manufacture electronic devices. At the heart of this process is PCB assembly services, a critical step in ensuring electronic components are mounted, connected, and functional. One standout technology in PCB assembly is the Ball Grid Array (BGA). Known for its efficiency and ability to support complex circuits, BGA has become a go-to solution for modern electronics manufacturers.

What Are PCB Assembly Services?

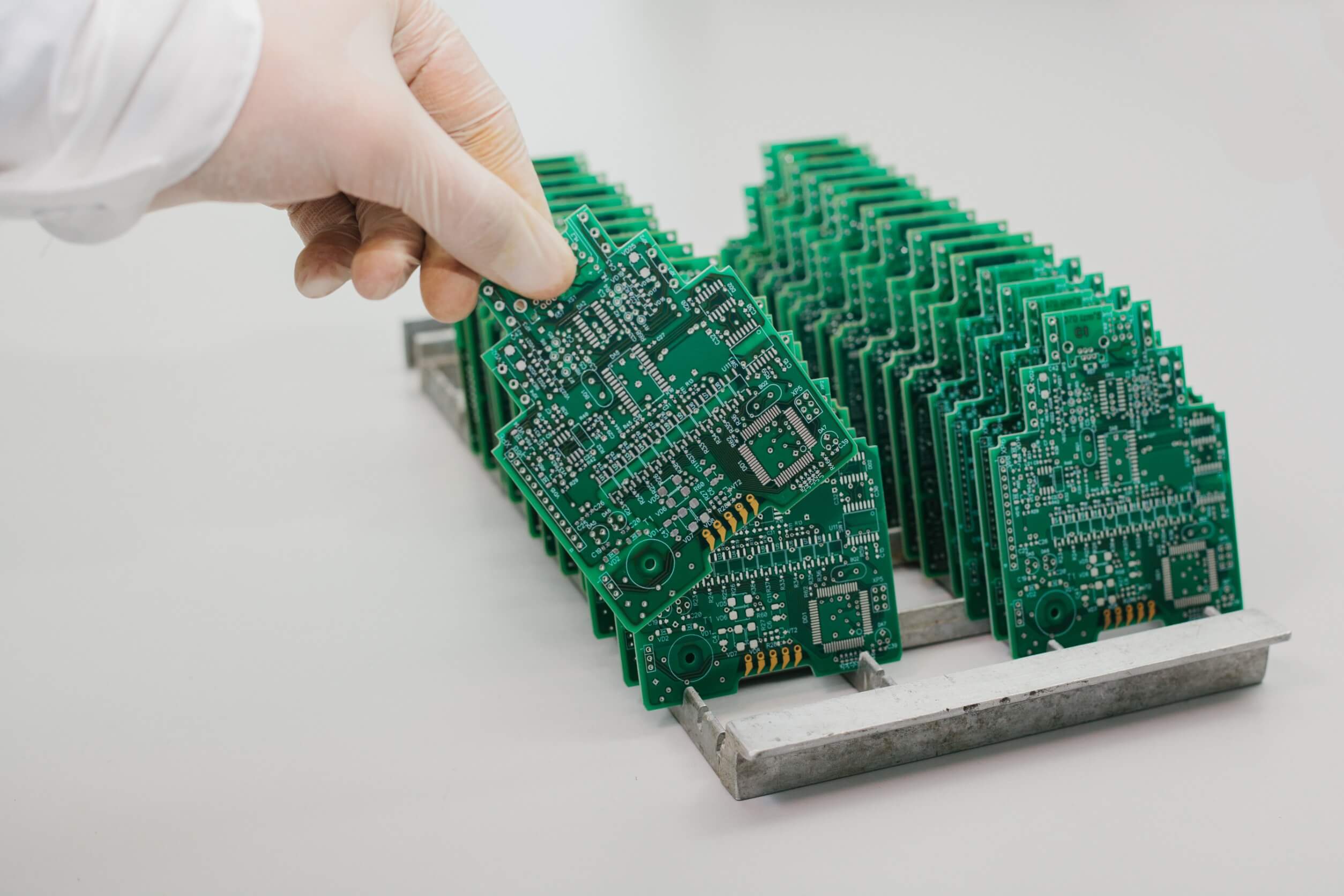

PCB assembly is the process of assembling electronic components onto a printed circuit board to make it fully operational. These boards act as the backbone of electronic devices, from smartphones and laptops to home appliances and medical equipment.

Key steps in PCB assembly

- Solder Paste Printing: Applying solder paste to specific areas of the board where components will be placed.

- Component Placement: Using automated machines to place components like resistors, capacitors, and microchips on the PCB with pinpoint accuracy.

- Reflow Soldering: Using controlled heat to solder components securely to the board.

- Inspection and Testing: Ensuring all components are correctly placed, soldered, and functioning as intended.

From single-layer boards to complex multilayer designs, PCB assembly brings electronic concepts to life with precision and reliability.

Why PCBs and assembly matter

Without PCBs, the world of electronics would lack the compact, efficient systems we rely on today. And at the centre of cutting-edge PCB assembly technology is the Ball Grid Array.

An Introduction to Ball Grid Array (BGA)

Put simply, a Ball Grid Array (BGA) is a type of surface-mount packaging used to connect highly complex integrated circuits to PCBs. Instead of traditional pins, BGAs use a grid of tiny solder balls that sit on the underside of a microchip.

This design offers several advantages, including better electrical performance, increased durability, and the ability to support smaller, more compact devices.

How does BGA work?

A BGA package consists of:

- A chip (integrated circuit)

- A substrate layer with an array of solder balls that interface with the PCB

- Microscopic pathways that connect the chip to the solder pads on the substrate.

When heat is applied during assembly (typically in a process called reflow soldering), the solder balls melt and form electrical connections between the chip and PCB. These connections deliver power and signals needed for the chip to function.

Applications of Ball Grid Array (BGA)

BGA technology has found a home in virtually every industry, thanks to its ability to meet the demands of modern electronics. Here are just a few applications:

- Consumer Electronics

From smartphones to laptops, most modern gadgets owe their compact designs to BGAs. They allow for high-density circuits with maximum performance in a minimal amount of space. For example:

- Smartphones pack microprocessors and memory chips in BGA packages, enabling slim and lightweight designs.

- Laptops leverage BGAs for GPU and CPU integration, ensuring powerful yet portable devices.

- Automotive

With advancements in autonomous driving and electric vehicles, cars now require more compact yet powerful electronics. BGAs play a key role in:

- Automotive sensors

- Advanced driver-assistance systems (ADAS)

- Electric powertrains

- Medical Equipment

The demand for portable and precise medical devices has made BGAs indispensable. Applications include:

- Wearable health monitors

- Imaging equipment

- Surgical navigation tools

- Telecommunications

For industries that rely on high-speed data transmission, BGAs are used in infrastructure like 5G base stations, network switches, and routers.

- Aerospace and Defense

Robust and efficient electronics are essential in environments where reliability is critical. BGA packages are favored for avionics systems, radar technology, and satellite communications.

Advantages of Ball Grid Array (BGA)

Why has BGA become a staple in PCB assembly services? The answer lies in its host of advantages that address the needs of increasingly complex electronics:

- High-Density Packaging

BGAs are perfect for compact designs requiring plenty of functionality squeezed into a small footprint. This high-density configuration saves precious space on the PCB while accommodating advanced systems.

- Improved Thermal Performance

Heat management is critical in electronics. Due to better heat dissipation across the solder balls, BGAs help avoid overheating, keeping devices cooler even during extensive use.

- Enhanced Electrical Performance

BGAs have shorter electrical paths compared to older pin-based packages. This reduces signal degradation, improves speed, and optimizes device performance.

- Reliability

BGA connections are more robust and less prone to mechanical failure. The spherical design of the solder balls also allows for better alignment during assembly, reducing defects.

- Cost-Efficiency

While advanced, BGA designs can lower manufacturing costs. Devices using BGAs often require fewer components and simplified circuitry, cutting production expenses in the long run.

- Compatibility with Automation

BGA assembly benefits from the high precision of automated placement and soldering tools, ensuring consistent quality and reducing errors during production.

Unlocking the Future of PCB Assembly with BGA

The rise of Ball Grid Array technology reflects the evolving needs of the electronics industry. From sleek smartphones and life-saving medical devices to self-driving cars, BGA packages are central to the efficiency and innovation we see today.

If you’re an engineer or business looking to optimize PCB assembly for your next product, consider leveraging the benefits of BGA technology. Its compact design, reliability, and cost-effectiveness make it the ideal choice for modern PCBs.

To explore how BGA can empower your products, contact your PCB assembly services provider for a consultation or to request custom solutions that unlock the full potential of your designs.

Leave a Reply