Introduction to Header Punches

Header punches play a crucial role in the metal forming industry. These tools shape and form metal into precise components. A high-quality header punch ensures accuracy, consistency, and longevity. Choosing the right header punches manufacturer is essential for optimal performance and durability.

Importance of Precision in Header Punches

Precision is a defining factor in header punch manufacturing. Manufacturers utilize advanced CNC technology to produce accurate punches. High precision ensures consistent results and reduces material wastage. Quality control measures further enhance the reliability of these tools.

Durability: A Key Factor in Header Punches

Durability is a crucial attribute of header punches. Manufacturers use hardened steel and carbide to enhance strength. Heat treatment processes improve wear resistance. A durable punch minimizes downtime and maintenance costs, ensuring long-term efficiency.

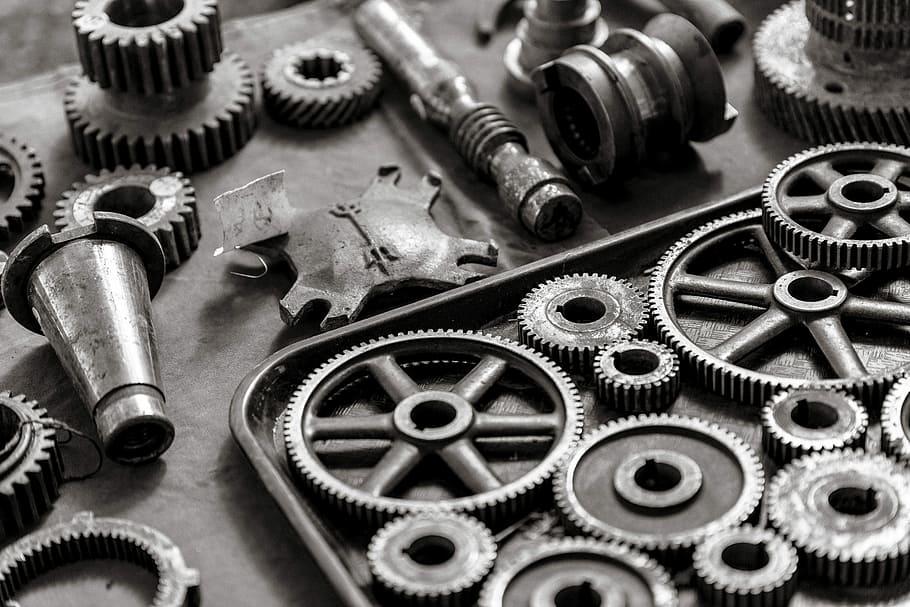

Materials Used in Header Punch Manufacturing

High-grade steel and carbide are common materials for header punches. These materials provide excellent hardness and toughness. Carbide punches offer superior wear resistance, making them ideal for high-volume production. Proper material selection ensures extended tool life.

Advanced Manufacturing Techniques

Top manufacturers use cutting-edge techniques to enhance quality. CNC machining, EDM, and precision grinding ensure superior accuracy. Advanced coating technologies, such as TiN and TiAlN, improve performance. These techniques increase wear resistance and reduce friction during operation.

Custom Header Punches for Specific Needs

Custom header punches cater to specific industrial applications. Manufacturers design punches based on client specifications. Customization includes material selection, coating options, and geometric designs. A tailored punch improves efficiency and meets production demands effectively.

Industries That Rely on Header Punches

Several industries depend on header punches for manufacturing. The automotive sector uses them to produce fasteners and engine components. The aerospace industry requires precision punches for structural parts. Medical device manufacturing also benefits from high-precision punches.

Quality Control in Header Punch Manufacturing

Strict quality control ensures the reliability of header punches. Manufacturers conduct hardness testing, dimensional inspections, and performance evaluations. ISO-certified facilities adhere to international standards. Consistent quality control prevents defects and enhances product performance.

Choosing the Best Header Punch Manufacturer

Selecting the right manufacturer is vital for obtaining high-quality punches. Look for experience, advanced technology, and positive customer reviews. A reputable manufacturer offers technical support and after-sales services. Partnering with a trusted supplier ensures reliable performance.

Conclusion: Investing in Quality Header Punches

Precision and durability define the best header punches. Choosing a top Cold heading dies manufacturer guarantees high performance and longevity. Advanced materials, strict quality control, and custom solutions enhance efficiency. Investing in high-quality header punches improves production output and reduces costs.

Leave a Reply