Polypropylene (PP) sheets have established themselves as essential materials in various industries due to their unique blend of strength, flexibility, and chemical resistance. Preferred by manufacturers and architects alike, PP sheets come in a variety of forms and thicknesses, allowing for a multitude of applications ranging from packaging and signage to automotive parts and construction. This Pulkit Plastic Products delves into the characteristics, applications, pricing factors, and future of PP sheets to provide a comprehensive understanding of this versatile material.

Characteristics and Composition of PP Sheets

Polypropylene sheets are made from polypropylene resin, a thermoplastic polymer known for its lightweight and durable nature. The molecular structure of polypropylene allows it to be molded and extruded into sheets of varying thickness, offering flexibility in design and functionality. One of the defining characteristics of PP sheets is their resistance to moisture and chemical corrosion, making them ideal for applications that require durability and flexibility.

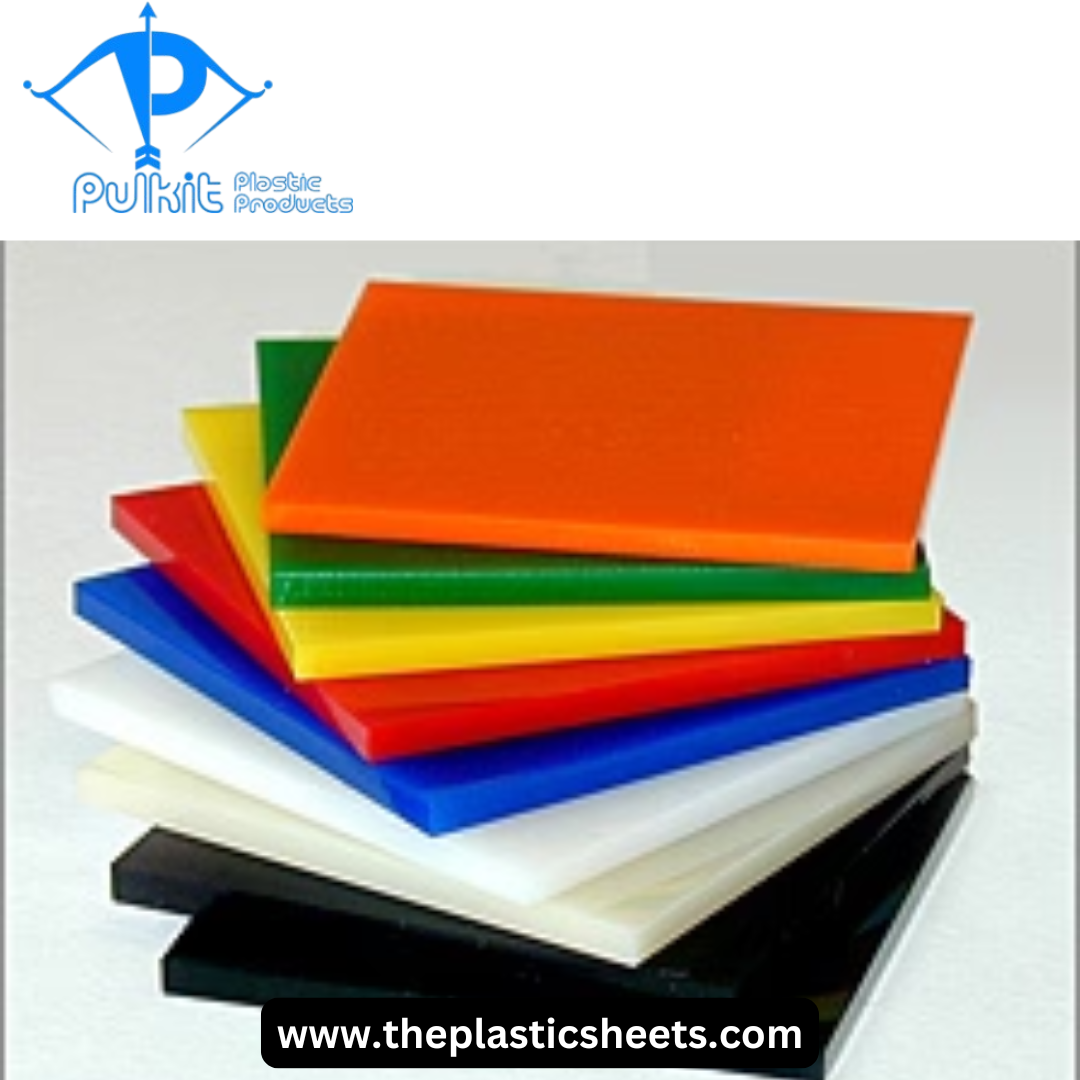

The clarity of PP sheets adds to their appeal; they can be produced in both transparent and opaque options, allowing for a wide variety of aesthetic finishes. The sheets can also be easily welded, cut, or printed on, making them suitable for signage, containers, and custom projects. As a result, architects and designers have embraced PP sheets due to their adaptability and the ease with which they can be incorporated into various design elements.

Applications of PP Sheets Across Industries

The diverse applications of PP sheets are what truly make them stand out in the marketplace. In the packaging industry, for instance, Polypropylene price are widely used to create lightweight yet sturdy containers for food products, cosmetics, and electronics. Their moisture-resistant nature protects contents from external contaminants, making them ideal for packaging sensitive items that require extra care.

In the construction sector, polypropylene sheets are utilized for weather barriers and insulation, protecting structures from moisture and enhancing energy efficiency. Additionally, these sheets are commonly used in the production of partitions and walls due to their aesthetic appeal and durability. Manufacturers also leverage PP sheets to create automotive parts, owing to their lightweight characteristics and resistance to chemicals, such as oils and detergents.

The signage industry benefits from the printability of PP sheets, which allows for high-quality graphics that can endure outdoor exposure. Whether creating point-of-purchase displays or outdoor banners, the versatility of PP sheets ensures that businesses can effectively communicate their messages while maintaining structural integrity.

Pricing Factors for PP Sheets

The price of PP sheets can vary widely based on several factors, including material quality, thickness, and production methods. In the context of the fluctuating market of raw materials, the polypropylene price has seen significant variation, influenced by oil prices and supply chain dynamics. The manufacturing process also plays a critical role; sheets produced through advanced methods may be priced higher due to the additional technology and innovation required.

Another determining factor is the thickness of the PP sheet. Thicker sheets tend to be more expensive because they require more raw material and undergo additional processing. Specialized finishes, such as UV resistance or embossed textures, will further contribute to variations in price. Buyers must consider their specific needs when evaluating the price for polypropylene sheets, as custom orders or specialized applications may incur extra costs.

Market trends also affect pricing—when demand spikes in specific industries, such as packaging or construction, it can lead to temporary increases in the cost of PP sheets. Therefore, consumers looking for competitive pricing should stay informed about market conditions to make well-timed purchases.

Advantages of Using PP Sheets

The numerous advantages of PP sheets make them a go-to choice for various applications. One of the most significant advantages is their cost-effectiveness. Due to their durability and lightweight nature, PP sheets help reduce shipping costs, making them an economical option for manufacturers and suppliers. They also offer substantial savings in production costs because they can often be formed and fabricated without complex machinery.

Another key benefit is their chemical resistance. PP sheets can withstand exposure to a wide range of acids, bases, and solvents, making them suitable for laboratory and industrial applications. This resistance extends to environmental factors, such as moisture and UV light, further enhancing their longevity and reducing the need for frequent replacements.

Moreover, the smooth surface of Price for polypropylene facilitates easy cleaning, making them ideal for environments that require stringent hygiene standards, like medical and food-processing facilities. Their versatility allows them to bend, shape, and adapt easily, accommodating various project requirements without compromising strength or integrity.

The Role of Sustainability in PP Sheet Production

As industries move toward more sustainable practices, the production of polypropylene sheets is evolving to align with eco-friendly initiatives. Many manufacturers are now focusing on creating PP sheets using recycled materials, reducing the demand for virgin plastics while promoting conservation of resources. This shift contributes to a circular economy, as post-consumer plastics are repurposed into usable sheet material.

Additionally, the recyclability of polypropylene itself adds to the environmental benefits. PP sheets can be recycled at the end of their life cycle, thus minimizing waste and contributing to a more sustainable manufacturing landscape. Companies that adopt sustainable practices not only meet regulatory requirements but also appeal to consumers who increasingly consider the environmental impact of their purchasing decisions.

By embracing sustainability, producers of PP sheets can not only enhance their public image but also streamline their operations. Innovations in recycling technology allow for more efficient recovery and processing of polypropylene, paving the way for a future where plastic products are managed more responsibly.

Future Trends in the PP Sheet Market

The future of PP sheets appears promising as technology continues to advance and the demand for sustainable materials grows. Emerging trends indicate a greater emphasis on customization, allowing customers to order specific sizes, colors, and finishes that meet their individual needs. This customization could be particularly beneficial for industries looking for unique branding opportunities.

Moreover, the integration of smart technologies into PP sheet applications is an exciting development on the horizon. For example, embedding sensors into PP sheets can lead to innovative products for the packaging industry, enhancing functionality and providing real-time inventory tracking. As technology reshapes manufacturing processes, the potential for advanced applications of PP sheets continues to expand.

Lastly, as the global market evolves, so too will the pricing dynamics in the polypropylene sector. Buyers can expect fluctuations influenced by economic conditions, supply chain disruptions, and advancements in manufacturing practices. Remaining informed about these market shifts will be imperative for those venturing into the PP sheets market in the coming years.

Conclusion

The Price of pp sheet represent a dynamic and highly versatile solution in the fields of packaging, construction, and manufacturing. Their unique combination of durability, lightweight properties, and chemical resistance makes them an ideal choice for a range of applications, providing numerous advantages, including cost-effectiveness and ease of use. With manufacturers focusing on sustainability and advancements in technology, the future of PP sheets is set to be both innovative and environmentally conscious.

Understanding the factors influencing the price for polypropylene and staying informed about market trends are essential for making informed purchasing decisions in this ever-evolving industry. As consumers increasingly prioritize sustainability, the role of PP sheets in meeting industry needs will only grow, cementing their status as a staple material in various sectors.

Frequently Asked Questions (FAQs)

-

What factors influence the price of PP sheets?

The price is influenced by factors such as material quality, thickness, production methods, market demand, and any specialized finishes required. -

Are PP sheets environmentally friendly?

Yes, PP sheets can be made from recycled materials and are fully recyclable at the end of their lifecycles, contributing to sustainability. -

What are the common applications for polypropylene sheets?

Common applications include packaging, signage, automotive parts, construction, and various industrial applications that require chemical resistance and durability. -

How can I ensure I am getting a good price for polypropylene sheets?

To secure a good price, stay informed about market conditions, consider ordering in bulk, and explore options from multiple suppliers to compare costs and quality.

Leave a Reply