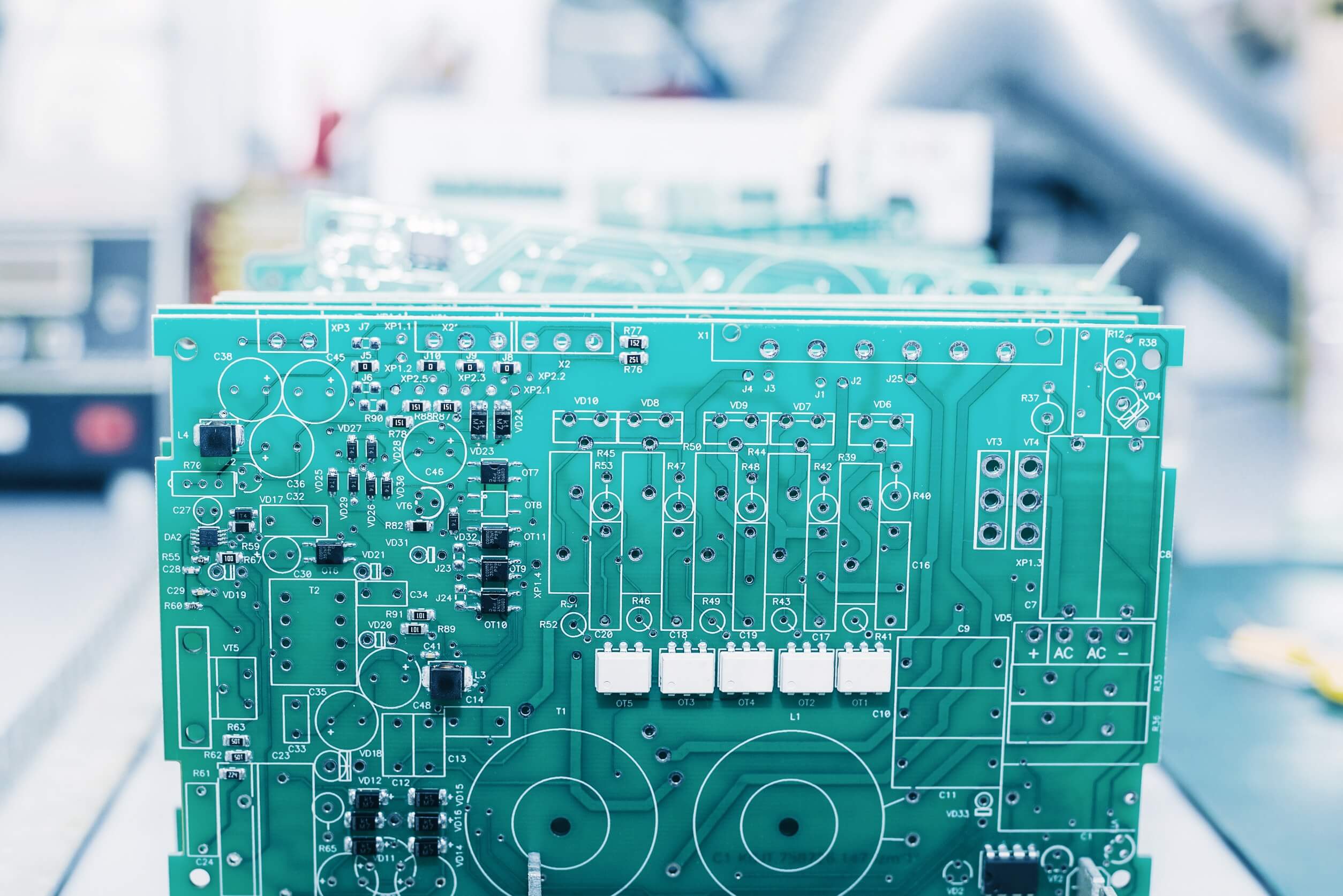

Ever wondered how that sleek smartphone in your hand or that compact drone in the air packs so much power and functionality? The secret lies in the magic of mixed printed circuit board assembly or PCBA. Mixed PCBA combines the best of both worlds – through-hole technology (THT) and surface mount technology (SMT) – to create powerful, versatile, and reliable devices. But how does this work, and why is it so beneficial?

What Is Mixed Printed Circuit Board Assembly?

To understand mixed PCB assembly, it helps to first understand the two core technologies behind it.

Through-Hole Technology (THT)

THT involves inserting electronic components with leads, or pins, through holes drilled in the PCB. These components are then soldered on the opposite side of the board to create a secure connection. THT is known for its durability and is often used in applications where components may experience mechanical stress, such as automotive or aerospace industries.

Surface Mount Technology (SMT)

SMT, on the other hand, allows components to be mounted directly onto the surface of the PCB without the need for drilled holes. It enables more compact and lightweight designs, making it favored for modern electronics like smartphones, laptops, and wearable devices.

Mixed PCBA

Mixed PCBA combines these two methods into a single, hybrid solution. It uses THT for components that demand durability and high reliability, and SMT for creating compact and intricate designs. This synergy allows manufacturers to build devices that are both robust and high-performing.

Think of it like assembling a dream team – you pick the strengths of each “player” (technology) to create the ultimate solution!

What Are the Benefits of Mixed PCBA?

Now that we’ve covered the basics, you might be wondering why companies go through the trouble of combining two different assembly processes. The answer lies in the benefits:

- Optimal Performance

Mixed PCB assembly ensures that every part of the board is tailored for its intended use. Components that require extra mechanical strength, like connectors, get the benefit of THT. Meanwhile, delicate yet space-saving parts, such as microchips, are mounted using SMT. This results in a PCB that delivers peak performance across all functions.

Imagine a race car with an engine built for speed and tires designed for durability – it’s the best of both worlds!

- Cost Efficiency

By strategically integrating THT and SMT, manufacturers can allocate resources more effectively. SMT is generally less labor-intensive and faster compared to THT, which can reduce production costs. At the same time, using THT for critical components prevents failures down the line, saving on costly repairs or replacements.

It’s a win-win for both manufacturers and end-users!

- Durability and Reliability

For applications where reliability is crucial – such as medical devices or industrial machinery – mixed PCB assembly is unmatched. The THT components provide a secure mechanical bond, which helps in environments that involve vibration, temperature fluctuations, or physical stress.

- Enhanced Design Flexibility

Mixed PCB assembly offers unparalleled flexibility in design. SMT’s smaller-sized components can be placed closer together, leaving more room for THT components that need extra reinforcement. This allows engineers to create products that are not only compact but also highly functional.

For example, imagine a printed circuit board in a smartwatch. The main processor can be surface-mounted for space efficiency, while the charging port can use through-hole technology for added durability during frequent use.

- Scalability

Mixed PCB assembly is scalable for all kinds of production – from small niche devices to high-volume consumer electronics. Manufacturers can adapt the process to suit the needs of the product, whether it’s a small run of custom boards or mass production.

- Supports Complex Electronics

Modern electronics often demand mixed PCB assembly to accommodate the complexity of new innovations. Devices like IoT sensors, drones, and smart appliances rely on this methodology to effectively integrate numerous functionalities in a small form factor.

Why Mixed PCB Assembly Matters

The use of mixed PCB assembly is growing rapidly as industries push the boundaries of what technology can achieve. From medical devices that improve lives to groundbreaking consumer gadgets, mixed PCB assembly is the backbone of innovation. Without such advanced assembly methods, we wouldn’t have the compact, reliable, and high-performing devices we rely on every day.

It’s also worth noting that mixed PCB assembly fosters sustainable practices. By using resources efficiently and creating durable products, manufacturers can help minimize electronic waste – a win for both businesses and the environment.

Final Thoughts

Mixed PCBA is proof that combining technologies can deliver something far greater than the sum of its parts. By leveraging the strengths of both through-hole and surface mount technologies, manufacturers can produce PCBs that are versatile, high-performing, and built to last.

Whether you are developing cutting-edge consumer electronics or creating sturdy industrial equipment, mixed PCB assembly is an essential tool for staying ahead in a competitive market.

Leave a Reply