In industries that deal with large quantities of materials, efficiency and accuracy are crucial. Whether it’s food grains, chemicals, fertilizers, or construction materials, bulk packaging plays a significant role in streamlining operations. This is where a jumbo bag packing machine becomes an invaluable asset. But how does this machine enhance efficiency in bulk packaging, and why is it essential for businesses? Let’s dive in and explore.

Understanding the Role of a Jumbo Bag Packing Machine

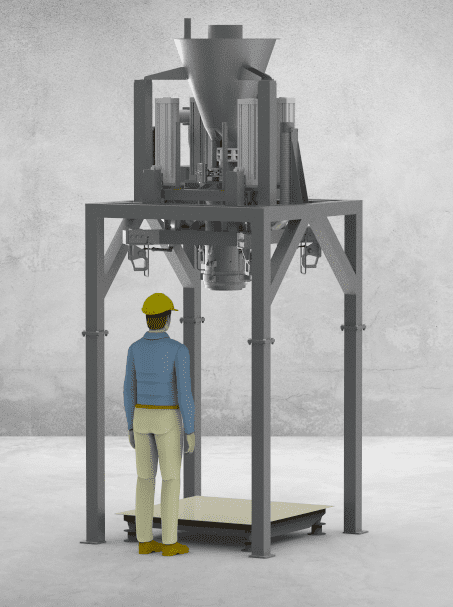

A jumbo bag packing machine is designed to fill and seal large bags, typically ranging from 500 kg to 2000 kg in capacity. These machines handle various types of dry, free-flowing materials, making them ideal for industries like agriculture, construction, and chemicals.

Traditional methods of packing large volumes require extensive labor, leading to inefficiencies, inconsistencies, and potential losses. A jumbo bag packing machine automates the process, ensuring precision, reducing waste, and improving productivity.

Key Benefits of a Jumbo Bag Packing Machine

1. Increased Efficiency and Speed

Manual packaging is time-consuming, but with a jumbo bag packing machine, the process becomes significantly faster. These machines are capable of handling tons of material within minutes, cutting down operational time and allowing businesses to focus on other critical tasks.

2. Accuracy and Reduced Material Loss

One of the biggest challenges in bulk packaging is weight accuracy. Overfilling results in product loss, while underfilling can cause regulatory compliance issues. A jumbo bag packing machine is equipped with advanced weighing systems that ensure precise measurement, reducing both material loss and financial setbacks.

3. Reduced Labor Costs

Manual packaging requires multiple workers, increasing labor costs. With automation, fewer hands are needed to operate the machine, leading to cost savings. Employees can be reassigned to other important tasks, improving overall workforce efficiency.

4. Improved Safety in the Workplace

Lifting and handling heavy bags manually pose risks such as back injuries and workplace accidents. A jumbo bag packing machine minimizes direct human involvement, enhancing workplace safety and reducing compensation claims due to injuries.

5. Consistent and Reliable Packaging

Uniform packaging is crucial, especially in industries that follow strict quality control measures. These machines ensure every bag is packed uniformly, reducing variations and maintaining a professional presentation.

How Does a Jumbo Bag Packing Machine Work?

Understanding the working process of a jumbo bag packing machine can help businesses appreciate its efficiency. Here’s a step-by-step breakdown:

- Bag Placement – An operator places an empty jumbo bag onto the filling station. The bag’s loops are securely attached to the holding hooks.

- Inflation & Stabilization – Many machines have an air inflation system that inflates the bag slightly before filling to ensure proper shape and stability.

- Material Feeding & Weighing – The material is fed into the bag through a controlled system that ensures precise measurement. The weighing system constantly monitors the weight to prevent under or overfilling.

- Settling & Compacting – Some machines include vibration systems that help settle the material, maximizing bag capacity while maintaining stability.

- Bag Sealing & Release – Once the bag is filled to the required weight, the top is sealed, and the bag is released onto a conveyor or pallet for transport.

This automated process reduces human errors, speeds up operations, and ensures efficiency at every step.

Choosing the Right Jumbo Bag Packing Machine for Your Business

When selecting a jumbo bag packing machine, businesses must consider several factors to ensure they get the best fit for their needs.

1. Type of Material Being Packed

Different materials have different flow properties. Powdery substances require dust-free systems, while granular materials need specialized feeding mechanisms. Understanding the type of material being packed helps in choosing the right machine specifications.

2. Weighing Accuracy

A high-quality weighing system ensures accurate filling, reducing product wastage. Look for machines with advanced load cells and programmable controls for precise measurements.

3. Automation Level

Some machines come with fully automated functions, including bag placement and sealing, while others may require partial manual handling. Choosing between semi-automatic and fully automatic models depends on production volume and budget.

4. Durability and Build Quality

A jumbo bag packing machine should be built with durable materials, especially if handling heavy loads daily. Stainless steel and robust structural components ensure longevity and low maintenance costs.

5. Ease of Maintenance and Support

Machines require regular maintenance to function efficiently. Opt for a machine with easily replaceable parts and reliable customer support for technical issues.

Industries That Benefit from a Jumbo Bag Packing Machine

Many industries rely on bulk packaging, and a jumbo bag packing machine plays a crucial role in improving efficiency. Here are some industries that benefit the most:

- Agriculture – Used for packaging grains, seeds, and fertilizers.

- Construction – Ideal for cement, sand, and other construction materials.

- Chemical Industry – Helps in safe and precise packing of powders and granules.

- Food Industry – Used for packing bulk flour, sugar, and other dry food items.

- Mining Industry – Suitable for minerals, ores, and other extracted materials.

The Future of Jumbo Bag Packing Machines

With technological advancements, jumbo bag packing machines are evolving to meet the demands of modern industries. Integration of IoT (Internet of Things) and AI-based monitoring systems allows for remote operation and real-time tracking of packaging performance.

Moreover, sustainability is becoming a key factor, with newer machines designed to minimize material wastage and energy consumption. Businesses investing in advanced jumbo bag packing machines can expect long-term benefits in both efficiency and environmental impact.

Final Thoughts

A jumbo bag packing machine is more than just an automation tool—it’s an essential investment for businesses dealing with bulk materials. From improving efficiency and accuracy to reducing labor costs and ensuring workplace safety, this machine transforms the packaging process for the better.

For industries looking to streamline their bulk packaging operations, adopting a jumbo bag packing machine is a smart move that ensures long-term productivity, cost savings, and consistent product quality.

Would you consider upgrading your packaging process with automation? Let us know how a jumbo bag packing machine could benefit your industry!

Leave a Reply