PP sheets, or polypropylene sheets, have gained traction as one of the most versatile materials used in numerous industries due to their robust properties and adaptability. This plastic sheet, made from polypropylene polymer, exhibits exceptional chemical resistance, lightweight nature, and considerable strength, making it suitable for a wide array of applications. Among manufacturers in India and worldwide, PP sheets are valued in sectors ranging from packaging and construction to automotive and healthcare. In this Pulkit Plastic Products, we will delve into the characteristics, manufacturing processes, applications, pricing dynamics, and various aspects regarding PP sheets to uncover why they remain a popular choice.

Understanding the Composition and Manufacturing of PP Sheets

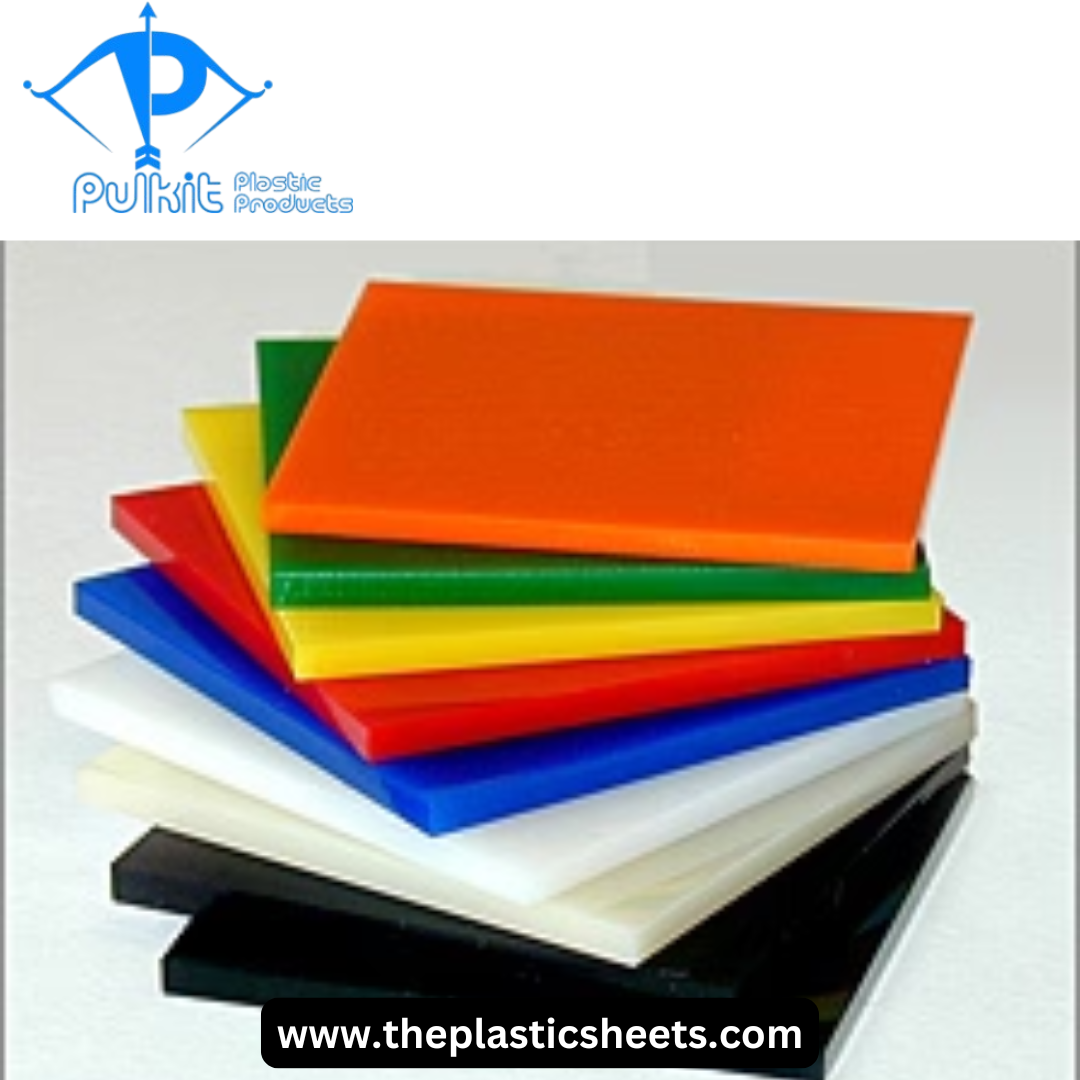

PP sheets are produced from polypropylene resin through a process of extrusion or molding. Polypropylene is a thermoplastic polymer known for its high tensile strength, which makes it preferable for various applications. The manufacturing process typically begins with the melting of polypropylene pellets which are then extruded into flat sheets of desired thicknesses and widths. These sheets can also be customized to achieve specific colors and textures, enhancing their aesthetic qualities.

Once the sheets are produced, they undergo cooling and solidifying phases, during which they retain their shape and properties. Additionally, additives can be introduced during manufacturing to enhance specific characteristics such as UV resistance, flame retardancy, or improved impact resistance. The ability to modify physical properties makes PP sheets immensely versatile, allowing manufacturers to cater to diverse market needs.

Given the advanced manufacturing technologies used by PP sheet manufacturers, these sheets can achieve varying degrees of thickness, surface finish, and opacity, further broadening their usability across different sectors. Furthermore, manufacturers can ensure consistency in quality, leading to greater reliability for applications that demand precision and durability.

Applications of PP Sheets Across Industries

The PP sheet manufacturer in india are used across a wide range of industries due to their numerous advantageous traits. In the packaging sector, for instance, the sheets are employed in creating rigid packaging solutions, including containers, boxes, and dividers. Their lightweight nature contributes to reduced shipping costs while maintaining robust protection for the items inside. This is particularly relevant for food packaging, where hygiene and resistance to moisture are vital.

In the construction industry, PP sheets are increasingly utilized for roofing, wall partitions, and insulation materials. The sheets’ strength and resistance to moisture make them an excellent choice for both interior and exterior applications. Furthermore, they can be used as lightweight alternative materials compared to traditional building materials, which can simplify transportation and installation processes.

In the automotive industry, PP sheets are utilized for interior and exterior components, such as dashboard covers, door panels, and storage compartments. Their ability to withstand high temperatures and resistance to chemicals make them extremely valuable for automotive applications, where performance and safety are paramount.

Healthcare is another significant sector employing PP sheets for medical packaging, disposable trays, and containers. The non-toxic and chemically resistant properties of these sheets ensure that they can maintain high hygiene standards, which are critical in medical environments. Thus, the versatility of PP sheets translates to their adaptable usage across various contexts, driven by industry-specific needs.

Advantages of Using PP Sheets

The advantages of PP sheets are manifold, contributing to their popularity in multiple sectors. One of the most prominent benefits is their lightweight nature, which makes them easy to handle and carry. This property is particularly important in sectors such as packaging and construction, where transport efficiency is crucial.

Another notable advantage is the high chemical resistance exhibited by PP sheets. These sheets can withstand exposure to various chemicals without deteriorating, making them suitable for industrial applications that require contact with aggressive substances. Their resistance to moisture, ultraviolet light, and temperature fluctuations further enhances their durability.

Additionally, PP sheets are highly customizable, allowing for tailored solutions that meet the specific needs of various industries. The ability to manipulate thickness, color, and texture empowers manufacturers to provide bespoke products that fit their customers’ requirements while improving overall functionality.

Moreover, PP sheets are recyclable, contributing to environmental sustainability. As businesses and consumers alike become more eco-conscious, choosing recyclable materials such as PP sheets aligns with modern sustainability goals. This attribute adds value to the material in sectors looking to decrease their carbon footprints and embrace green initiatives.

Pricing Dynamics of PP Sheets

Understanding the pricing dynamics of PP sheets manufacturer is crucial for businesses looking to incorporate this material into their operations. The price of PP sheets can fluctuate based on various factors, including raw material costs, manufacturing techniques, and market demand. The primary component, polypropylene resin, is affected by fluctuations in petroleum prices, as its production relies heavily on oil-derived products.

Generally, PP sheets price varies depending on their thickness, size, and any custom features such as colors or finishes. Bulk orders often come with discounts, enabling businesses to save costs, especially for high-volume production. Manufacturers can adjust pricing strategies based on market conditions, ensuring that their products remain competitive while meeting customer demands.

Additionally, the location of the manufacturer plays a role in pricing. For instance, being a major player within the manufacturing landscape, India has various PP sheet manufacturers that can provide competitive pricing due to lower labor and production costs. By identifying reliable PP sheet manufacturers in India, businesses can explore options for both quality and affordability.

Given these dynamics, businesses are encouraged to compare the offerings and prices from various manufacturers to secure the best deals while ensuring that quality is not compromised. Establishing long-term relationships with manufacturers may also yield favorable pricing arrangements and better service responses.

Exploring PP Sheet Manufacturers in India

India is home to numerous PP sheet manufacturers contributing significantly to the global market. With a robust manufacturing ecosystem, many companies in India produce high-quality polypropylene sheets tailored to meet domestic and international demands. These manufacturers embrace advanced technologies and skilled labor to create products that ensure reliability and performance.

When choosing a PP sheet manufacturer in India, factors such as production capacity, quality certifications, and customer service are paramount. Engaging with manufacturers who adhere to global quality standards assures businesses that they are receiving durable and reliable products. Furthermore, many manufacturers in India are increasingly adopting sustainable practices and exploring eco-friendly methods to enhance the environmental benefits of their produced sheets.

Exploring the local manufacturing capabilities in India allows organizations to overcome challenges associated with international shipping and reduce lead times. Working with local manufacturers provides added advantages, including the ability to communicate directly, request customizations, and arrange for efficient logistics.

Innovations Driving the Future of PP Sheets

Innovation continues to shape the future of PP sheets, resulting in enhanced functionalities and applications. Developments in material science have led to the emergence of advanced formulations for PP sheets that improve properties such as impact resistance, adhesion, and bio-resilience. These innovations open doors for new applications in diverse fields such as agriculture, construction, and environmental management.

Technological advancements in manufacturing processes are also moving toward greater efficiency and sustainability. Companies are adopting automated production lines and lean practices aiming to reduce waste and optimize resource usage. The incorporation of smart manufacturing principles allows for improved traceability, quality control, and timely delivery of products.

Moreover, the growth of bioplastics and bio-based alternatives is influencing the polypropylene sheet PP sheets price are a remarkable material that offers a unique combination of durability, versatility, and sustainability, making them highly valuable across numerous industries. The diverse applications of PP sheets, along with their beneficial properties such as lightweight nature and chemical resistance, position them as a preferred choice for manufacturers and consumers alike.

As businesses look to integrate PP sheets into their operations, understanding the intricacies of pricing dynamics, choosing quality manufacturers, and keeping an eye on innovative developments will be crucial. With the continuous advancements in materials and processes, PP sheets are set to maintain and expand their significance in the global market.

Frequently Asked Questions

-

What are the primary uses of PP sheets?

PP sheets are used in various applications, including packaging, construction, automotive components, and healthcare products due to their lightweight, durable, and chemical-resistant properties. -

How are PP sheets priced, and what factors influence their cost?

The price of PP sheets can vary based on thickness, size, and customizations. Factors such as raw material costs and market demand also play significant roles in determining PP sheets prices. -

Where can I find reliable PP sheet manufacturers in India?

Several manufacturers in India specialize in producing PP sheets. It’s advisable to research local companies, check certifications, and read reviews to find reputable manufacturers. -

Are PP sheets recyclable?

Yes, PP sheets are fully recyclable, making them an environmentally friendly choice. Recycling PP contributes to sustainable practices while helping businesses minimize their ecological impact.

Leave a Reply