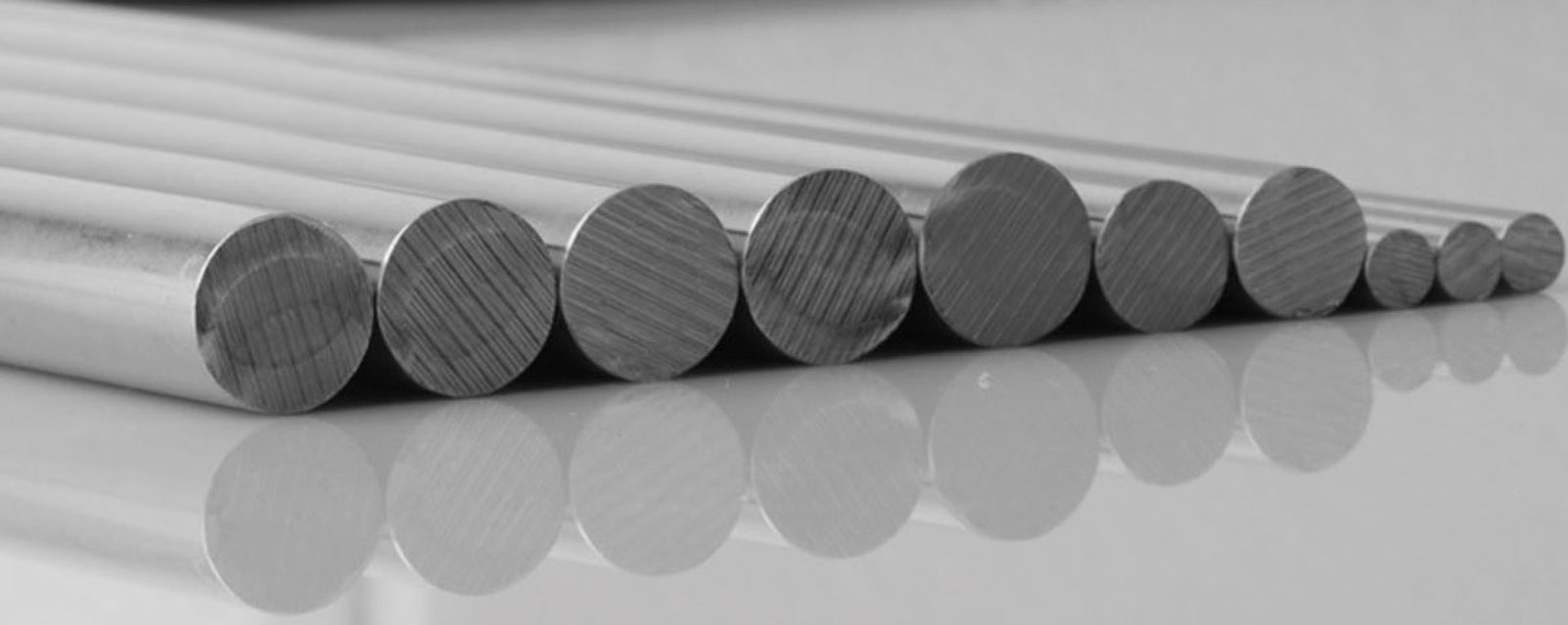

Aluminium round bars are a popular choice in numerous industries due to their strength, durability, and versatility. These bars are widely used in construction, automotive, aerospace, and marine industries, among others. Their adaptability makes them essential in various applications, ranging from structural components to decorative elements.

What is an Aluminium Round Bar?

An aluminium round bar is a cylindrical piece of aluminium that is commonly used in manufacturing and engineering applications. It is known for its excellent corrosion resistance, lightweight properties, and high strength-to-weight ratio. These characteristics make aluminium round bars ideal for projects where strength and weight are critical factors.

Types of Aluminium Round Bars

1. 6061 Aluminium Round Bar

6061 aluminium round bars are among the most versatile and widely used. They offer excellent corrosion resistance, good machinability, and high strength. These bars are suitable for structural applications, aerospace components, and even recreational equipment.

2. 6063 Aluminium Round Bar

6063 aluminium round bars are known for their excellent corrosion resistance and smooth surface finish. They are often used in architectural applications, such as window frames, door frames, and decorative trims.

3. 7075 Aluminium Round Bar

7075 aluminium round bars are known for their high strength and toughness. They are commonly used in aerospace applications, automotive parts, and sporting goods. Although they are less corrosion-resistant than other grades, their superior strength makes them a preferred choice in high-stress environments.

4. 5083 Aluminium Round Bar

5083 aluminium round bars offer excellent corrosion resistance, especially in marine environments. They are used in shipbuilding, oil rigs, and chemical tankers. Their high resistance to seawater makes them ideal for marine applications.

Benefits of Using Aluminium Round Bars

1. Lightweight

Aluminium round bars are significantly lighter than steel, which makes them ideal for applications where weight reduction is crucial. This property is particularly beneficial in the aerospace and automotive industries, where reducing weight can improve fuel efficiency and performance.

2. Corrosion Resistance

Aluminium is naturally resistant to corrosion, making it suitable for use in harsh environments. This resistance extends the lifespan of aluminium round bars, reducing the need for frequent replacements and maintenance.

3. High Strength-to-Weight Ratio

The high strength-to-weight ratio of aluminium round bars means they can withstand significant loads without adding excessive weight. This property is valuable in structural applications, where strength and durability are paramount.

4. Machinability

Aluminium round bars are easy to machine, cut, and shape. This machinability allows for precise customizations and complex designs, making them suitable for various manufacturing processes.

5. Recyclability

Aluminium is 100% recyclable, making aluminium round bars an environmentally friendly choice. Recycling aluminium requires less energy compared to producing new aluminium, reducing the overall carbon footprint.

Applications of Aluminium Round Bars

1. Construction

In construction, aluminium round bars are used for structural supports, railings, and decorative elements. Their lightweight and corrosion-resistant properties make them ideal for both indoor and outdoor use.

2. Automotive Industry

The automotive industry uses aluminium round bars for various components, including engine parts, chassis, and suspension systems. The lightweight nature of aluminium helps improve vehicle fuel efficiency and performance.

3. Aerospace Industry

In the aerospace industry, aluminium round bars are used in the manufacturing of aircraft structures, wings, and fuselages. Their high strength-to-weight ratio is essential for ensuring safety and efficiency in flight.

4. Marine Industry

Aluminium round bars are widely used in the marine industry for shipbuilding, yacht construction, and offshore platforms. Their excellent resistance to seawater and harsh marine environments ensures durability and longevity.

5. Machinery and Equipment

In machinery and equipment manufacturing, aluminium round bars are used to produce various components, such as gears, shafts, and fittings. Their machinability and strength make them suitable for heavy-duty applications.

How to Choose the Right Aluminium Round Bar

1. Consider the Application

The intended use of the aluminium round bar should guide your choice. For example, 6061 aluminium is suitable for general-purpose applications, while 7075 is better for high-stress environments.

2. Evaluate Strength Requirements

Different aluminium alloys offer varying levels of strength. Ensure you choose an alloy that meets the strength requirements of your project.

3. Check Corrosion Resistance

If the application involves exposure to corrosive environments, such as marine or chemical settings, opt for aluminium alloys with higher corrosion resistance, like 5083 or 6063.

4. Determine Machinability

For projects that require extensive machining or custom shaping, select an aluminium round bar with good machinability to ensure ease of processing.

Conclusion

Aluminium round bars are an indispensable material in various industries due to their lightweight, strength, corrosion resistance, and versatility. By understanding the different types, benefits, and applications of aluminium round bars, you can make informed decisions for your projects. Whether you’re in construction, automotive, aerospace, or marine industries, aluminium round bars offer a reliable solution for your structural and manufacturing needs.

Leave a Reply