In the world of industrial applications, certain materials stand out due to their remarkable properties. Alloy 600, also known as Inconel 600, is one such material that has earned a reputation for its superior resistance to heat and corrosion. When it comes to alloy 600 flanges, this nickel-chromium alloy excels in both high-pressure and high-temperature environments, making it an indispensable part of industrial piping systems.

In this blog, we will explore the characteristics of Alloy 600, the types of flanges made from this material, their benefits, and their applications in various industries.

What Is Alloy 600?

Alloy 600 is a high-performance, corrosion-resistant material composed of 72% nickel, 14-17% chromium, and iron. Its design allows it to withstand extreme temperatures and resist corrosion in highly acidic or alkali-rich environments.

Key Characteristics:

- Exceptional Corrosion Resistance: Ideal for industries dealing with chemicals, salts, and harsh substances.

- Temperature Resistance: Functions well in high-temperature settings, withstanding temperatures up to 2000°F (1093°C).

- High Strength: Retains strength even under stress, ensuring reliability in high-pressure applications.

These properties make Alloy 600 flanges a crucial component in systems that operate under harsh conditions.

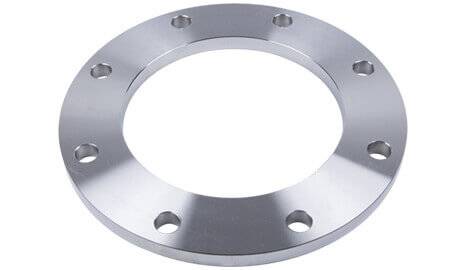

Types of Alloy 600 Flanges

When it comes to choosing Alloy 600 flanges, there are several types to consider. Each type serves a specific function, and selecting the right one for your application is crucial. Here are the most common types of Alloy 600 flanges:

-

Weld Neck Flanges

Weld neck flanges have a long tapered neck, which helps distribute stress evenly across the piping system. This type is best suited for high-pressure and high-temperature applications. -

Slip-On Flanges

Easy to install and more affordable, slip-on flanges are commonly used in lower-pressure applications where ease of installation is a priority. -

Blind Flanges

Blind flanges are used to seal the end of a pipe or vessel, preventing any flow. They are ideal for testing, inspection, or in systems where flow needs to be temporarily halted. -

Socket Weld Flanges

Ideal for small-diameter piping systems, socket weld flanges provide a strong and leak-proof connection. They are often used in high-pressure applications. -

Threaded Flanges

Threaded flanges are used when welding is not an option. They are easy to install and remove, making them a practical choice for systems requiring disassembly. -

Lap Joint Flanges

These flanges are used in combination with stub ends and are easy to align and maintain. They are useful in systems that need frequent disassembly.

Advantages of Alloy 600 Flanges

There are several reasons why Alloy 600 flanges are chosen over other materials for industrial piping systems. Here are some of the key benefits:

-

Corrosion Resistance

Alloy 600 is highly resistant to oxidation, reducing the risk of corrosion in harsh chemical or marine environments. -

High-Temperature Resistance

Its ability to retain strength and integrity at extreme temperatures makes it suitable for applications involving heat exchangers, turbines, and boilers. -

Durability and Longevity

With its outstanding mechanical strength and resistance to wear, Alloy 600 flanges are known for their long service life, reducing the frequency of replacements and maintenance. -

Versatile Applications

Alloy 600 is suitable for a wide range of industries, including petrochemical, aerospace, and power generation, due to its impressive versatility. -

Cost-Effectiveness

While Alloy 600 flanges may have a higher initial cost compared to standard flanges, their durability and low maintenance needs lead to long-term savings.

Common Applications of Alloy 600 Flanges

Due to its impressive properties, Alloy 600 flanges are used across various industries, particularly those dealing with high heat and chemical exposure. Here are some key industries where these flanges are commonly used:

1. Chemical Processing

Alloy 600 flanges are widely used in reactors, piping systems, and heat exchangers that handle corrosive chemicals.

2. Power Generation

They are crucial in power plants, including those that use steam turbines and boilers, where high temperatures and pressure are common.

3. Aerospace

In aerospace engineering, Inconel 600 flanges are used in jet engines and other components that are exposed to extreme heat.

4. Oil and Gas

Offshore rigs, refineries, and pipelines frequently utilize these flanges due to their resistance to seawater corrosion and other aggressive substances.

5. Marine Engineering

In shipbuilding and underwater applications, Alloy 600 flanges offer excellent protection against chloride-induced corrosion.

6. Food and Beverage

Alloy 600 is also used in the food industry, particularly in systems that must resist acids and other food-related chemicals.

How to Choose the Right Alloy 600 Flange

Selecting the right Alloy 600 flange depends on several factors. Here’s a quick guide to help you choose the best option for your needs:

-

Application Type

Determine whether your system is low or high pressure, and select a flange type that suits your operational requirements. -

Size and Pressure Rating

Consider the flange’s size, pressure rating, and temperature capacity to ensure it matches your system’s specifications. -

Flange Type

Choose between the various flange types (weld neck, slip-on, blind, etc.) based on your system’s design and maintenance needs. -

Seal Integrity

Make sure the flange type and material are compatible with your gasket and sealing requirements to avoid leaks. -

Compliance and Certification

Always choose flanges that meet relevant industry standards and regulations to ensure safety and reliability.

Tips for Maintaining Alloy 600 Flanges

Proper maintenance of Alloy 600 flanges ensures their long-term performance. Here are some tips to keep them in optimal condition:

-

Inspection and Monitoring

Regularly inspect the flanges for signs of corrosion, cracks, or damage to avoid costly failures. -

Cleaning and Decontamination

Clean the flanges from any chemical residue, dirt, or buildup to prevent deterioration and maintain their strength. -

Proper Installation

Ensure that flanges are correctly aligned and tightened to prevent undue stress on the components. -

Avoid Over-tightening

When tightening bolts, avoid over-tightening, as this can damage the flange and lead to leaks. -

Lubrication

Use appropriate lubricants on the flange bolts to ensure easy installation and removal, especially in systems that need disassembly.

Conclusion

Alloy 600 flanges are an essential component for systems that require strength, durability, and resistance to extreme temperatures and corrosion. Their versatility across industries like chemical processing, power generation, aerospace, and oil & gas makes them an indispensable part of industrial piping systems.

By selecting the right flange type, considering your application needs, and following proper maintenance practices, you can ensure the reliability and longevity of these critical components.

Focus Keywords: Alloy 600 flanges, Inconel 600 flanges, high-temperature flanges, corrosion-resistant flanges, nickel-chromium flanges.

Leave a Reply