Introduction

The Benzoic Acid Manufacturing Plant Project Report provides a comprehensive guide for establishing a facility dedicated to the production of benzoic acid. Known for its widespread industrial applications, benzoic acid serves as a preservative, chemical intermediate, and additive in various industries, including food, pharmaceuticals, and cosmetics. This report outlines the manufacturing process, infrastructure requirements, market dynamics, and financial considerations to ensure the success of such a venture.

Overview of Benzoic Acid

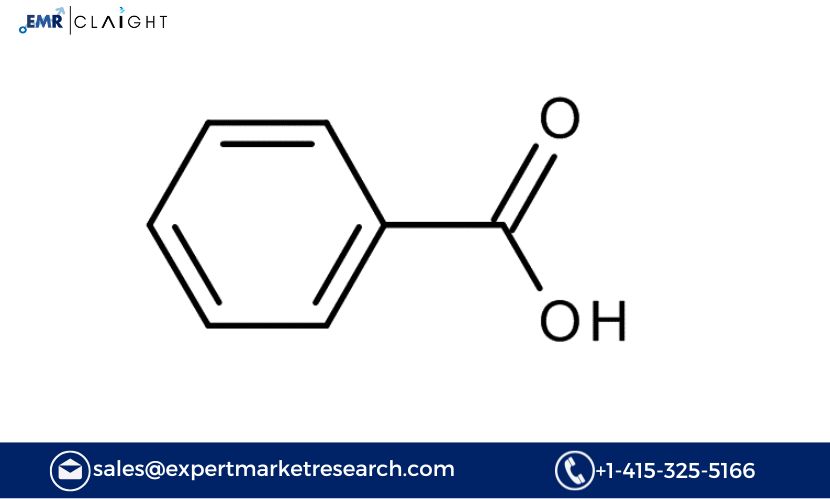

Chemical Properties

Benzoic acid (C₆H₅COOH) is a crystalline white compound that occurs naturally in certain plants and fruits. It has a melting point of 122°C and is slightly soluble in water. Benzoic acid’s chemical structure makes it highly effective as an antimicrobial agent, which is why it is extensively used as a preservative in acidic food products.

Key Applications

- Food Industry:Acts as a preservative under the code E210, preventing microbial growth in acidic foods like soft drinks, pickles, and sauces.

- Pharmaceutical Industry:Used in formulations for antifungal ointments, skin creams, and as a pH adjuster in medicines.

- Chemical Industry:Plays a critical role in the synthesis of alkyd resins, benzyl benzoate, and other organic compounds.

- Cosmetic Industry:Functions as a preservative and stabilizer in personal care products.

Get a Free Sample Report with Table of Contents@

Manufacturing Process

The production of benzoic acid involves several well-established industrial methods. Each process has its own advantages depending on the scale, availability of raw materials, and end-use requirements.

1. Toluene Oxidation Process

This is the most widely used method for commercial benzoic acid production.

- Raw Materials: Toluene and oxygen (or air).

- Process:

- Toluene is oxidized in the presence of cobalt or manganese-based catalysts at elevated temperatures.

- The reaction produces benzoic acid, which is then crystallized and purified.

- Advantages:

- High efficiency.

- Minimal environmental impact due to low by-product formation.

2. Hydrolysis of Benzotrichloride

This process involves the controlled hydrolysis of benzotrichloride.

- Raw Materials: Benzotrichloride and water.

- Process:

- Benzotrichloride reacts with water in the presence of a base to yield benzoic acid.

- Advantages:

- Suitable for specialty applications.

3. Neutralization of Benzoate Salts

- Raw Materials: Sodium benzoate or potassium benzoate.

- Process:

- Acidification of the benzoate salt with a strong acid produces benzoic acid.

- Advantages:

- Simpler process.

- Often used in small-scale production.

Infrastructure and Machinery Requirements

1. Key Equipment

To achieve efficient and scalable production, the following equipment is required:

- Reactors: For chemical oxidation or hydrolysis.

- Crystallizers: To purify and isolate benzoic acid.

- Filtration Systems: To remove impurities and solid by-products.

- Dryers: For moisture removal from the final product.

- Storage Tanks: To safely store raw materials and finished goods.

2. Plant Layout and Design

- Location: Proximity to raw material suppliers and transportation hubs.

- Utilities: Reliable access to electricity, water, and waste disposal facilities.

- Safety Features: Adequate ventilation, fire safety systems, and spill containment measures.

Market Potential and Trends

Benzoic acid enjoys steady demand due to its versatile applications across various industries.

1. Global Market Insights

- Growth Drivers:

- Rising demand for preservatives in packaged foods.

- Increasing use of benzoic acid derivatives in the chemical industry.

- Expansion of the pharmaceutical and cosmetics sectors.

- Key Markets:

- North America and Europe: Stringent food safety standards drive demand.

- Asia-Pacific: Rapid industrialization and growth in the food and beverage sector.

2. Future Trends

- Growing interest in environmentally friendly production processes.

- Increased demand for benzoic acid in emerging markets due to urbanization and changing lifestyles.

Financial Considerations

Setting up a benzoic acid manufacturing plant requires detailed financial planning.

1. Capital Investment

- Fixed Costs:

- Land acquisition, plant construction, and procurement of machinery.

- Variable Costs:

- Raw materials, utilities, labor, and maintenance.

2. Operating Costs

- Energy consumption for running reactors and dryers.

- Costs associated with waste treatment and environmental compliance.

3. Revenue Streams

- Sale of benzoic acid to various industries.

- By-product utilization, depending on the manufacturing process.

Regulatory Compliance

Manufacturers must adhere to stringent regulatory standards to ensure product quality and environmental safety.

1. Food Safety Regulations

Compliance with FDA, EU, and other regional standards for benzoic acid as a food preservative.

2. Environmental Regulations

- Proper treatment of emissions and wastewater to minimize environmental impact.

- Adherence to guidelines for the storage and handling of chemicals.

3. Worker Safety

Implementation of safety protocols, including personal protective equipment (PPE) and training programs.

Benefits of Setting Up a Benzoic Acid Manufacturing Plant

Steady Market Demand

The diverse applications of benzoic acid ensure a consistent demand, making it a profitable venture.

Scalability

The production process can be scaled to meet market needs, from small-scale to large-scale operations.

Export Potential

High demand in global markets offers opportunities for export-oriented growth.

Steps to Establish the Plant

- Conduct a Feasibility Study:Assess market demand, raw material availability, and economic viability.

- Secure Funding:Obtain capital through loans, investments, or government grants.

- Site Selection and Construction:Choose a location with access to utilities and transport infrastructure.

- Procurement and Installation:Purchase high-quality machinery and set up the production line.

- Quality Control:Implement stringent testing procedures to ensure product purity.

FAQ

1. What is benzoic acid used for?

Benzoic acid is primarily used as a preservative in the food industry, a chemical intermediate in the production of resins and plasticizers, and in pharmaceutical formulations.

2. What raw materials are needed for benzoic acid production?

Common raw materials include toluene, catalysts like cobalt or manganese, and water.

3. Is benzoic acid safe for use in food?

Yes, benzoic acid is safe when used within regulated limits, as specified by food safety authorities.

4. What are the major markets for benzoic acid?

Key markets include North America, Europe, and the Asia-Pacific region, driven by demand in the food, chemical, and pharmaceutical industries.

5. How can benzoic acid production impact the environment?

While the production process can generate emissions, modern facilities use advanced technologies to minimize environmental impact through efficient waste management and emission control systems.

6. What is the typical production capacity of a benzoic acid plant?

Production capacity varies based on plant size, ranging from small-scale operations (a few tons per day) to large-scale facilities producing hundreds of tons daily.

Media Contact

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A.

Email: sales@expertmarketresearch.com

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au

Leave a Reply