In the realm of packaging solutions, polypropylene (PP) woven bags have emerged as a leading option for businesses across various sectors. These bags, made from woven polypropylene fabric, are known for their strength, versatility, and eco-friendliness. As organizations seek more sustainable packaging solutions, the popularity of PP woven bags is on the rise. This Pulkit Plastic Products delves into the characteristics, applications, manufacturing processes, pricing factors, and the landscape of PP woven bag manufacturers.

Understanding PP Woven Bags

PP woven bags are produced from polypropylene granules that are extruded into thin filaments and woven together to form a durable fabric. This fabric is then fashioned into bags of varying sizes and shapes, often tailored for specific use-cases. The weaving process endows these bags with remarkable tensile strength, making them ideal for carrying heavy loads while maintaining their shape.

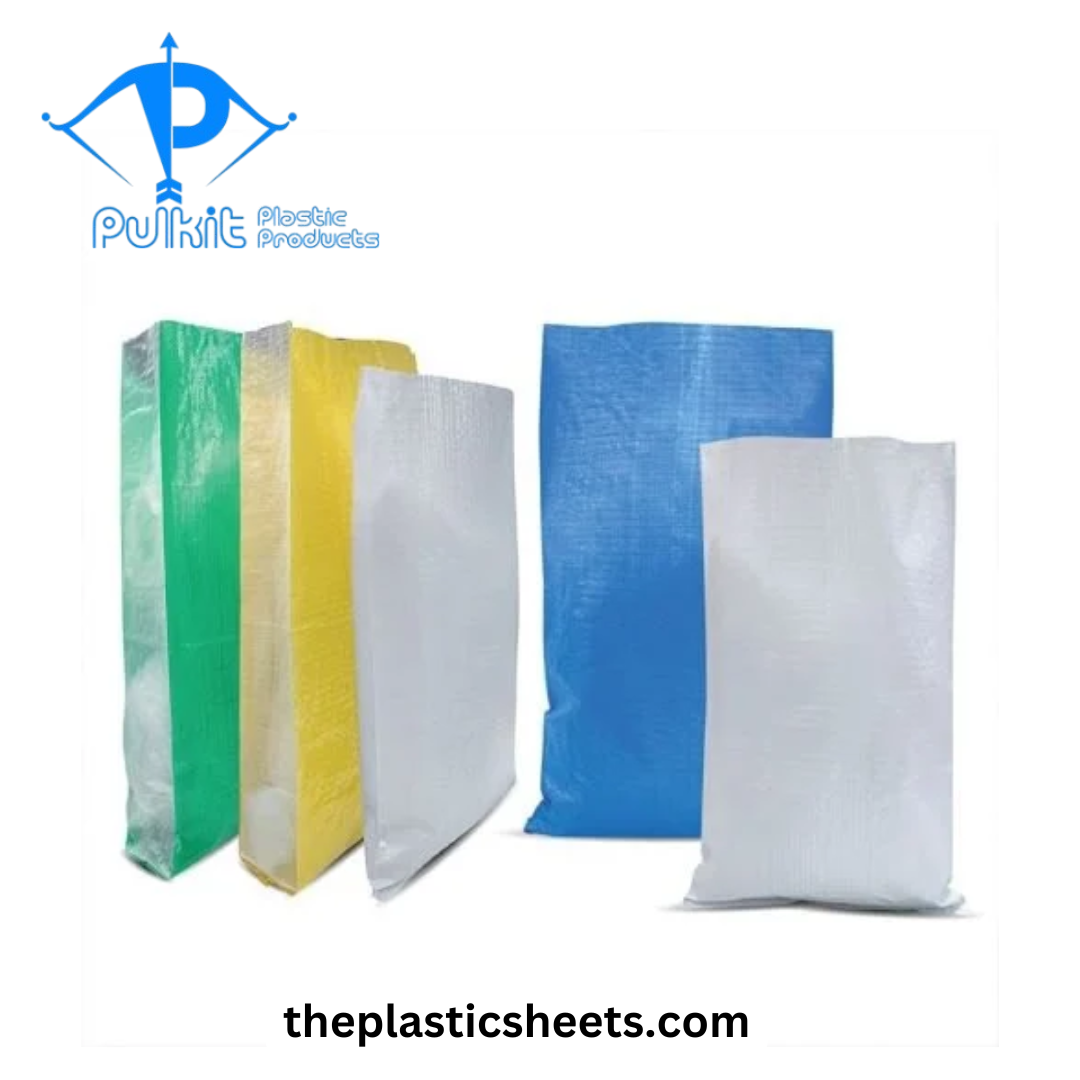

One of the standout features of PP woven bags is their resistance to water, chemicals, and UV radiation, making them suitable for both indoor and outdoor applications. They come in various designs, including flat bags, gusseted bags, and bags with handles, offering versatility to meet the demands of different industries. Furthermore, businesses can take advantage of customized designs to print logos or brand messages directly on the bags, adding an additional layer of marketing.

Applications of PP Woven Bags

The adaptability of PP woven bag manufacturers finds utility across diverse industries, from agriculture to construction. Below are several common applications:

1. Agriculture

In the agricultural sector, PP woven bags are widely used for packaging grains, seeds, fertilizers, and animal feed. Their durability and protection against moisture make them suitable for long-term storage. Farmers benefit from using these bags as they help preserve the quality of their products while fostering easy transportation from farms to marketplaces.

2. Food Packaging

PP woven bags have been adopted by the food industry for packaging bulk food products like rice, sugar, flour, and snacks. Many manufacturers ensure that their bags are food-grade compliant, thus providing a safe solution for storing and transporting food items. Their ability to prevent pests and moisture intrusion is particularly valuable for maintaining the freshness of food products.

3. Construction and Building Materials

Construction companies favor PP woven bags for transporting sand, cement, gravel, and other materials. The strength of these bags ensures they can withstand the rigors of heavy handling and transportation. Additionally, their resistance to moisture helps keep the materials dry, preventing degradation during transit.

4. Retail and Consumer Goods

In the retail sector, PP woven bags are popular for reusable shopping bags. Many brands are opting for these bags as an eco-friendly alternative to single-use plastic bags, promoting sustainable practices among consumers. The ability to print vibrant designs makes them visually appealing, enhancing brand visibility.

Manufacturing Process of PP Woven Bags

The manufacturing of PP woven bags involves several critical processes that transform raw polypropylene into finished products. Understanding this process provides insights into the quality and functionality of these bags:

-

Extrusion: The process begins with the extrusion of polypropylene pellets, where they are melted and formed into thin film strands. These strands form the basic raw material for woven bags.

-

Weaving: The extruded filaments are woven together to create a strong fabric. The weaving technique employed can vary based on the desired strength and texture of the final product. Common weaving patterns include plain weave, twill weave, and special types such as circular weaving.

-

Cutting and Sewing: Once the woven fabric is produced, it is cut into specific dimensions based on the intended bag size. The edges are then sewn with durable thread to create seams, ensuring that the bags hold their shape and can withstand weight.

-

Finishing and Quality Control: After the bags are sewn, they undergo finishing processes such as printing, lamination, or coating to enhance their durability. Thorough quality checks ensure that the bags meet established strength and durability standards.

-

Packaging and Distribution: Finally, the finished bags are packaged for distribution to wholesalers and retailers, ready for use by consumers and businesses alike.

Factors Influencing PP Woven Bag Prices

Understanding the PP woven bags images is essential for businesses looking to incorporate these bags into their operations. Several factors influence pricing:

1. Material Costs

The primary material for PP woven bags is polypropylene, whose price can fluctuate based on market conditions, oil prices, and supply-demand dynamics. Manufacturers need to keep track of these costs, as they significantly impact the final price of the bags.

2. Bag Specifications

The complexity of the bag’s design, including size, shape, and required features, can affect the cost. Custom orders that require unique dimensions or printing can lead to higher prices compared to standard bags.

3. Production Volume

Typically, ordering in bulk can result in lower prices per unit due to economies of scale. Many manufacturers offer discounts for larger orders, making it cost-effective for businesses needing substantial quantities.

4. Shipping and Handling

Shipping costs can also vary based on the distance from the manufacturer, weight, and the volume of the order. These costs should be considered in the overall pricing strategy.

The Landscape of PP Woven Bag Manufacturers

As the demand for PP woven bags continues to grow, so does the number of manufacturers in the market. A variety of companies globally specialize in producing these bags, each offering unique features and pricing structures. Some notable aspects of this competitive landscape include:

-

Diversity of Offerings: Many manufacturers provide a wide range of products, from standard bags to heavily customized options tailored to specific industries. This diversity allows businesses to choose suppliers that align with their unique needs.

-

Quality and Compliance: As with any product, the quality of PP woven bags can vary between manufacturers. Reputable companies ensure that their products meet international standards, especially for food-grade applications, reassuring customers of their safety and durability.

-

Sustainability Efforts: Increasingly, manufacturers are focusing on eco-friendly production practices and offering recyclable or biodegradable options. This responsiveness to environmental concerns is becoming an integral part of attracting customers in today’s market.

-

Global Reach: Many manufacturers are extending their reach beyond local markets, offering their products internationally. This globalization means businesses have a broader scope for sourcing their packaging solutions, potentially leading to better pricing and availability.

Conclusion

The PP Woven Bag price have solidified their position as a favored packaging solution across numerous industries, thanks to their strength, versatility, and eco-friendliness. From agricultural applications to retail uses, the adaptability of these bags caters to a variety of market needs. Understanding the manufacturing processes, pricing factors, and the competitive landscape of PP woven bag manufacturers equips businesses to make informed decisions in sourcing their packaging solutions. As sustainability continues to shape consumer preferences, the market for PP woven bags is likely to expand even further.

Frequently Asked Questions (FAQs)

-

What are the benefits of using PP woven bags?

PP woven bags offer several benefits, including high strength, water and UV resistance, eco-friendliness, and the ability for customization. They are suitable across various industries, from agriculture to construction. -

How can I find reliable PP woven bag manufacturers?

To find trustworthy manufacturers, consider researching online, reading customer reviews, and visiting trade shows. It may also be helpful to request samples to assess the quality of their products before making a larger order. -

What should I expect in terms of lead time for custom PP woven bags?

Lead times for custom PP woven bags can vary based on the manufacturer, design complexity, and order volume. Generally, expect anywhere from a few weeks to several months, so it’s advisable to plan accordingly. -

Are PP woven bags recyclable?

Yes, PP woven bags are recyclable, making them a more sustainable option compared to traditional plastic bags. Many manufacturers encourage the recycling of their bags, contributing to a circular economy.

Leave a Reply