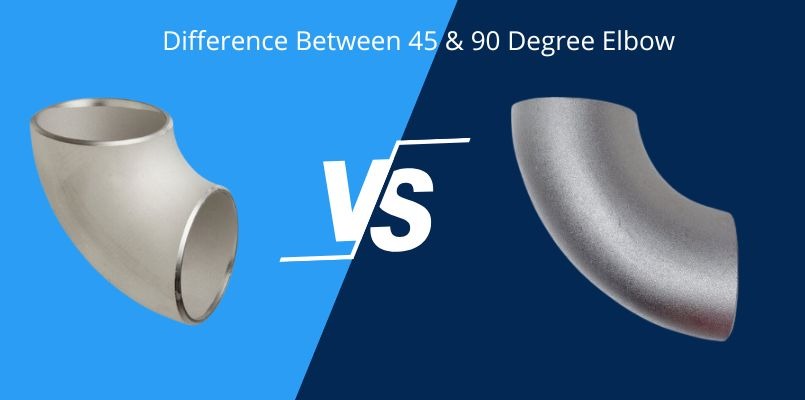

When working with piping systems, elbow fittings play an essential role in ensuring proper flow direction and efficient system design. Among the most commonly used elbow fittings are the 45-degree elbow and the 90-degree elbow. While they may seem similar, their applications, benefits, and limitations vary significantly depending on the scenario.

What is a 45-Degree Elbow?

The 45-degree elbow is a pipe fitting used to change the direction of flow by 45 degrees. This fitting is rounded and gently curved, allowing the fluid to flow smoothly without causing significant turbulence or pressure loss.

Applications of a 45-Degree Elbow

But what is a 45-degree elbow used for? Here are the key applications:

-

Pipeline Direction Change

A 45-degree elbow is commonly used in situations where a gradual change in direction is required. This makes it ideal for systems where maintaining smooth flow is critical. -

Gravity-Fed Systems

The gentle slope provided by this elbow makes it an excellent choice for gravity-fed systems, such as in drainage or irrigation pipelines. -

Reducing Pressure Loss

For applications where pressure loss must be kept to a minimum, a 45-Degree Elbow is preferred as it reduces sudden changes in direction that often increase resistance and energy consumption. -

Aesthetic Layouts

Often, 45-degree elbows are installed in applications where the piping system needs to look neat or align better with architectural features, such as in HVAC systems.

Benefits of a 45-Degree Elbow

Choosing a 45-degree elbow brings several advantages:

-

Reduced Turbulence

The gentle directional change minimizes turbulence in the flow, improving efficiency. -

Lower Pressure Drop

The gradual angle reduces resistance, which helps maintain higher system efficiency. -

Improved Durability

By lowering the strain caused by abrupt directional changes, 45-degree elbows contribute to longer-lasting systems.

What is a 90-Degree Elbow?

The 90-degree elbow, on the other hand, is used to create a sharp turn in the piping system. It changes the direction of flow by 90 degrees, forming a right angle. This type of elbow is commonly found in household plumbing and industrial setups.

Applications of a 90-Degree Elbow

What is a 90-degree elbow used for? Here are its primary applications:

-

Tight Spaces

A 90-degree elbow is often used in compact systems where making a sharper turn is necessary to fit within the available space. -

Vertical to Horizontal Flow

These elbows are frequently used to connect vertical and horizontal pipes in plumbing and drainage systems. -

Industrial Piping Systems

They are favored in industrial settings to direct the flow of liquids, gases, or other materials with precision. -

Furniture and DIY Projects

Uniquely, 90-degree elbows are also employed in non-plumbing applications such as steel framework or furniture assembly due to their sharp angle.

Benefits of a 90-Degree Elbow

Using 90-degree elbows provides notable benefits, including:

-

Compact Design

This fitting allows for tight and sudden directional changes, making it perfect for confined spaces. -

Standardized Use

Their universal design is widely available and compatible with most piping systems. -

Ease of Installation

The sharp turn requires fewer additional fittings, simplifying the installation process.

Comparing 45-Degree and 90-Degree Elbows

Flow Dynamics

The 45-degree elbow is smoother, offering better flow dynamics with minimal resistance. On the contrary, the 90-degree elbow is sharper, which can result in higher friction and turbulence.

Key Considerations for Choosing the Right Elbow

-

Application Requirements

Does your system need a gentle bend or a sharp turn? Consider the flow characteristics and pressure requirements. -

Space Constraints

Examine whether your piping layout has enough room for a 45-Degree Elbow or 90-Degree Elbow is a better fit for compact areas. -

Material Compatibility

Ensure the material of the elbow matches your pipe and is suitable for the operating conditions, such as temperature and pressure. -

Maintenance Needs

Systems prone to blockages or high-wear conditions may require fittings that are easier to clean or replace, favoring smoother designs.

Space Requirements

A 90-degree elbow is ideal for tight spaces due to its sharp bend, while the 45-degree elbow requires more installation room to accommodate its gradual slope.

Energy Efficiency

When it comes to energy and pressure efficiency, the 45-degree elbow generally outperforms the 90-degree elbow thanks to its reduced resistance in fluid movement.

Cost and Availability

Both types of elbows are affordable and readily available in various materials like stainless steel, copper, and PVC. However, the choice depends on your project needs.

Final Thoughts

Both 45-degree elbows and 90-degree elbows serve distinct purposes in piping systems, offering unique advantages and limitations depending on the situation. By considering factors like flow efficiency, space availability, and application requirements, Neo Impex Stainless Pvt. Ltd. provides a wide range of high-quality elbows to meet diverse needs. With the right choice of elbow, you can optimize performance in your piping systems effectively.

Leave a Reply